New hi pressure chemical injection building

- USED-A

- Item No. EA0000316

- Share

Details

- Quantity:

- 1

- Status:

- USED-A

- Unit Type:

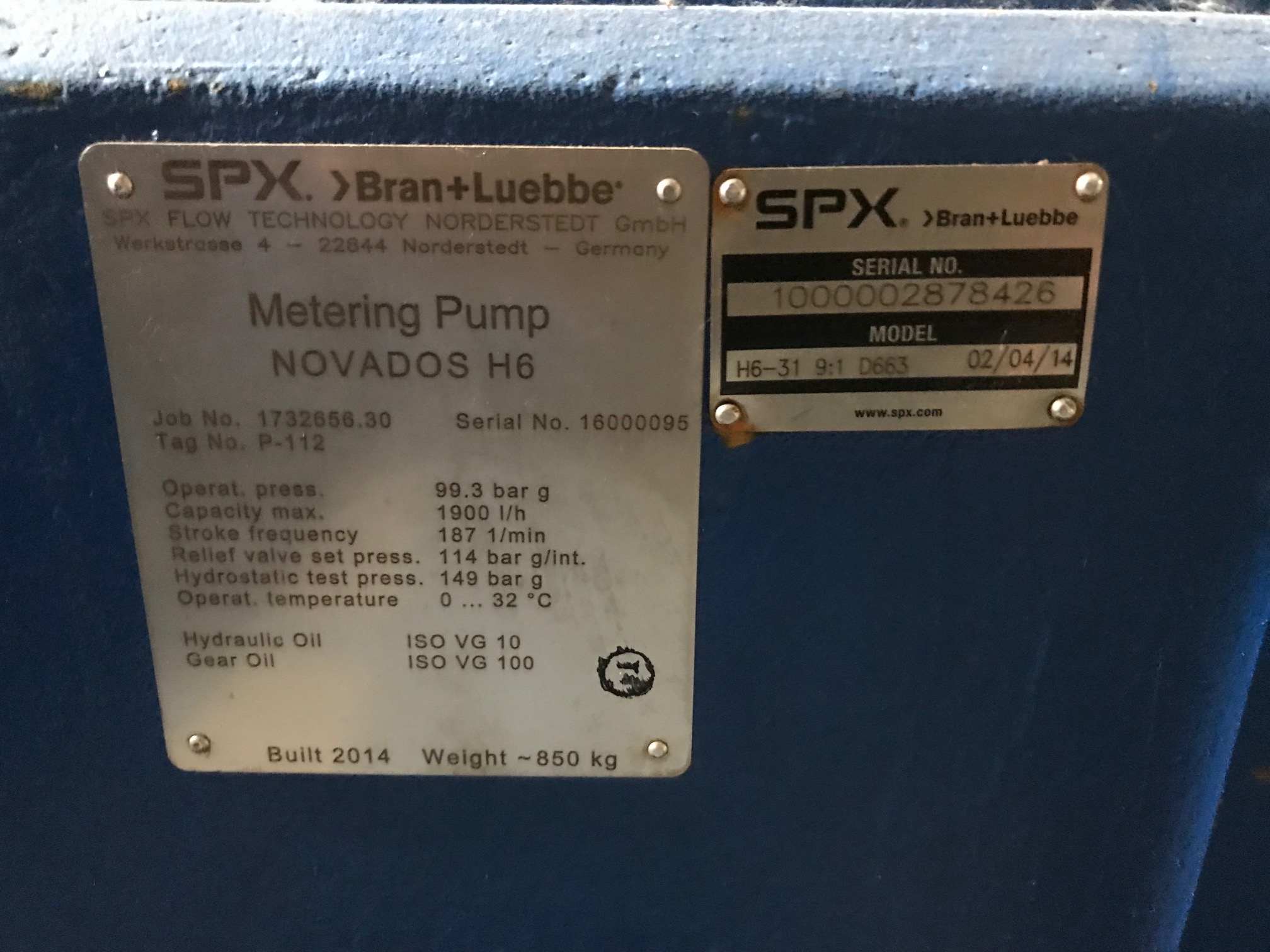

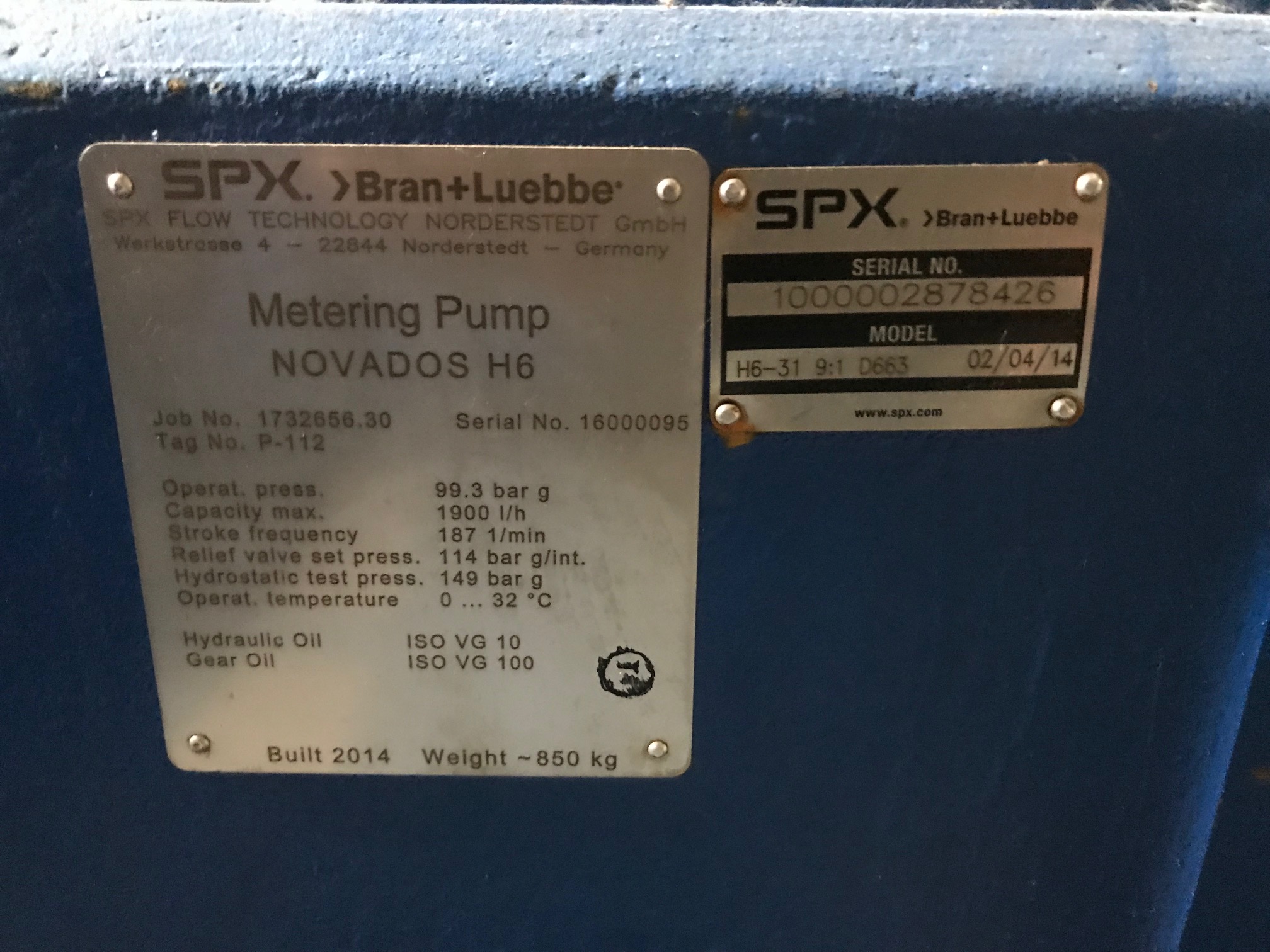

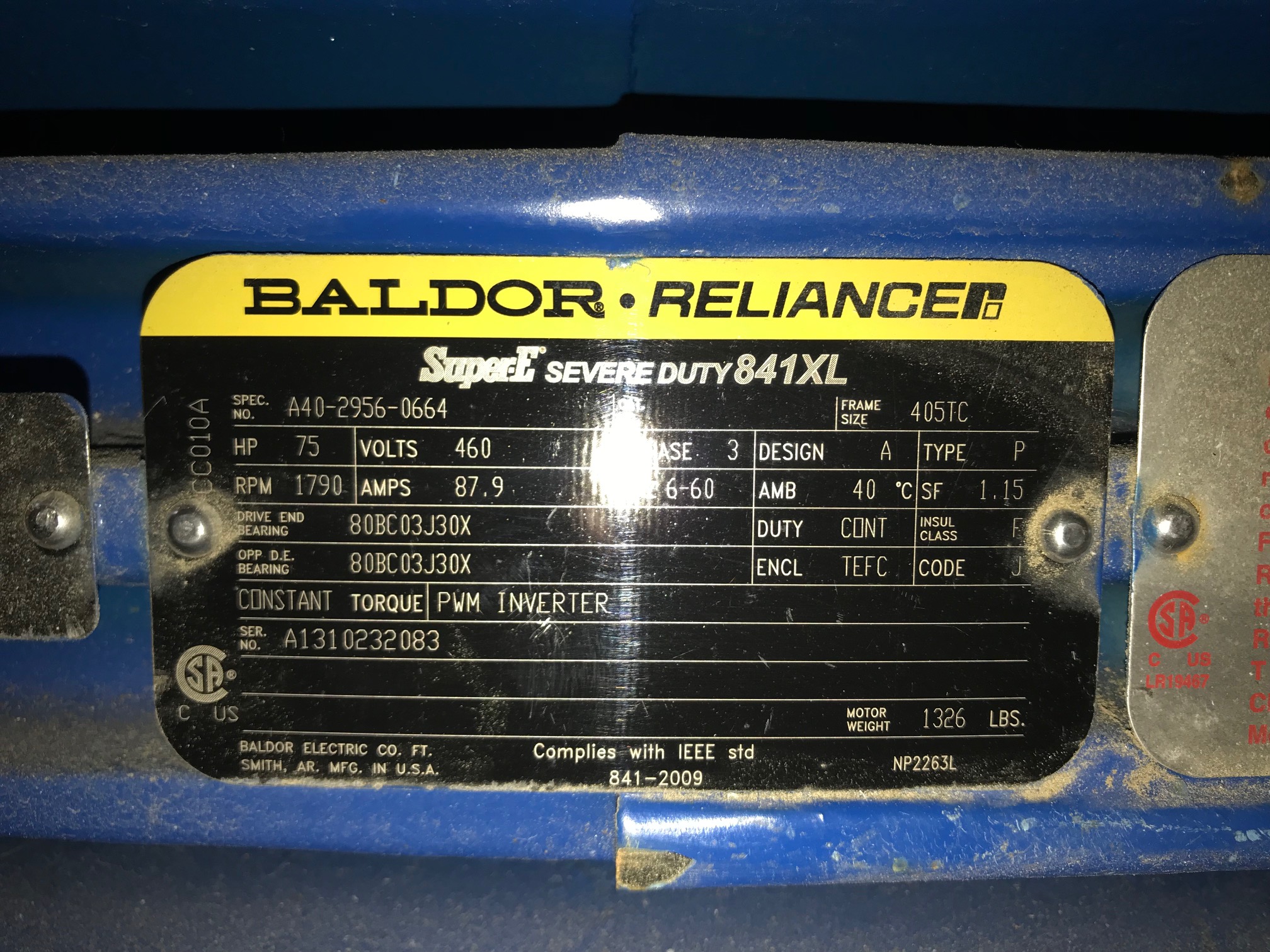

- Injection Pump Skid

- Location:

- Lloydminster

- Listing Date:

- 20/11/2019

Description

Specifications:

Tanks:

(2) 2200 L Double walled tank, 50 ID x 72

Long, 7 Kpa max op. pressure (Clemmer)

(2) 3050 L Double walled tank, 50 ID x 98.5

Long, 7 Kpa max op. pressure (Clemmer)

ASTM A36 / 36M construction, ULC S601

double wall standard

Each tank includes two sight level gauges

with isolation valves

Support stand built with structural HSS

tubing and wide flange beam

(CWB Certified welding)

Building:

12-0 wide x 25-0 long x 13-0 low eave, 14-0

high eave, shed style roof with a 1:12 slope

22 gauge pre-painted exterior walls, roof

and trim (Warwick standard stock colors)

R-12 fibre glass batt insulation in the walls

and R-20 in roof with a 6-mil vapor barrier

throughout

24 gauge white fluted aluminum interior

liner

(2) 6 x 7 double steel man door (16 ga

frame, 18 ga door, R12

insulated) c/w 88TP locking panic hardware,

hydraulic door closure, IWG window in both

leafs, kick plates, aluminum

threshold, check chain, weather-stripping and

canopy

(3) 12 x 12 stamped louvers c/w interior

sliders and (1) 36 x 36 Sliding Window

(1) 12 explosion proof exhaust fan c/w

hood, 120/1/60 (based on 12 ACPH)

(1) Ruffneck FX5 electric heater

Skid:

12 x 25 skid, 12 wide flange construction, checker plate floor, lifting lugs, and high density foam

insulation applied to bottom of skid (CWB Certified welding)

P. Eng stamped design (BC Registered)

Paint:

Sandblast to SSPC SP-6 Spec

1 Coat of Tan Cloverdale DTM Paint

Pump System & Piping:

1 SS Autoclave tubing, valves, and fittings will be supplied by others for P-111 pump discharge

1/2 316SS Swagelok tube fittings with twin ferrule valves will be used for P-113 pump discharge

Techlok fittings will be supplied by Ultrafab

Flexible hose will be used on the pump suction lines, 316SS inner bellows with 304SS outer braid

(3) 1 x 1 NPT 316SS Farris PSVs for pump recycle bypass

(3) Pressure Switches - 1/2" NPT, Electric, 3000psi MAWP (CCS

6900GZE22)

Electrical:

Building Area Classification - Class 1, Div 2 as per Canadian Electrical Code

Low voltage installation will be done using aluminum conduit and (1)

Hammond junction box Brands used are Crouse-Hinds, Hoffman, Meyers, and Weidmuller

a. (4) Crouse-Hind On/Off switches, one for each pump and one for the heater.

b. (1) Det-Tronics MIR flame detector with Carbon Controls beacon.

c. (1) Carbon Controls ESD mushroom push button w/ safety shroud

d. (1) Exhaust fan - 12 x 12, explosion proof

**FINANCING AVAILABLE**

Please email Cody@energyauctions.ca for viewing availability, price and finance options

For all purchase inquiries, please contact us via email at cody@energyauctions.ca or telephone at (403) 771-3984

- 5% GST (Goods & Service Tax) where applicable on all sales will be applied.

- International tax exemption rules will apply.

- Buyer will receive an invoice immediately following confirmation, wiring instructions for payment will accompany.

- All items are sold "as is, where is" unless otherwise stated in the "details description".

Send a quote/offer to receive the listing owners contact details now.