95 HP Skid Mounted Screw Compressor Package. Brand NEW!

- NEW

- Item No. EA0000352

- Share

Details

- Quantity:

- 1

- Status:

- NEW

- Unit Type:

- Compressor

- Location:

- Stettler

- Listing Date:

- 21/04/2020

Description

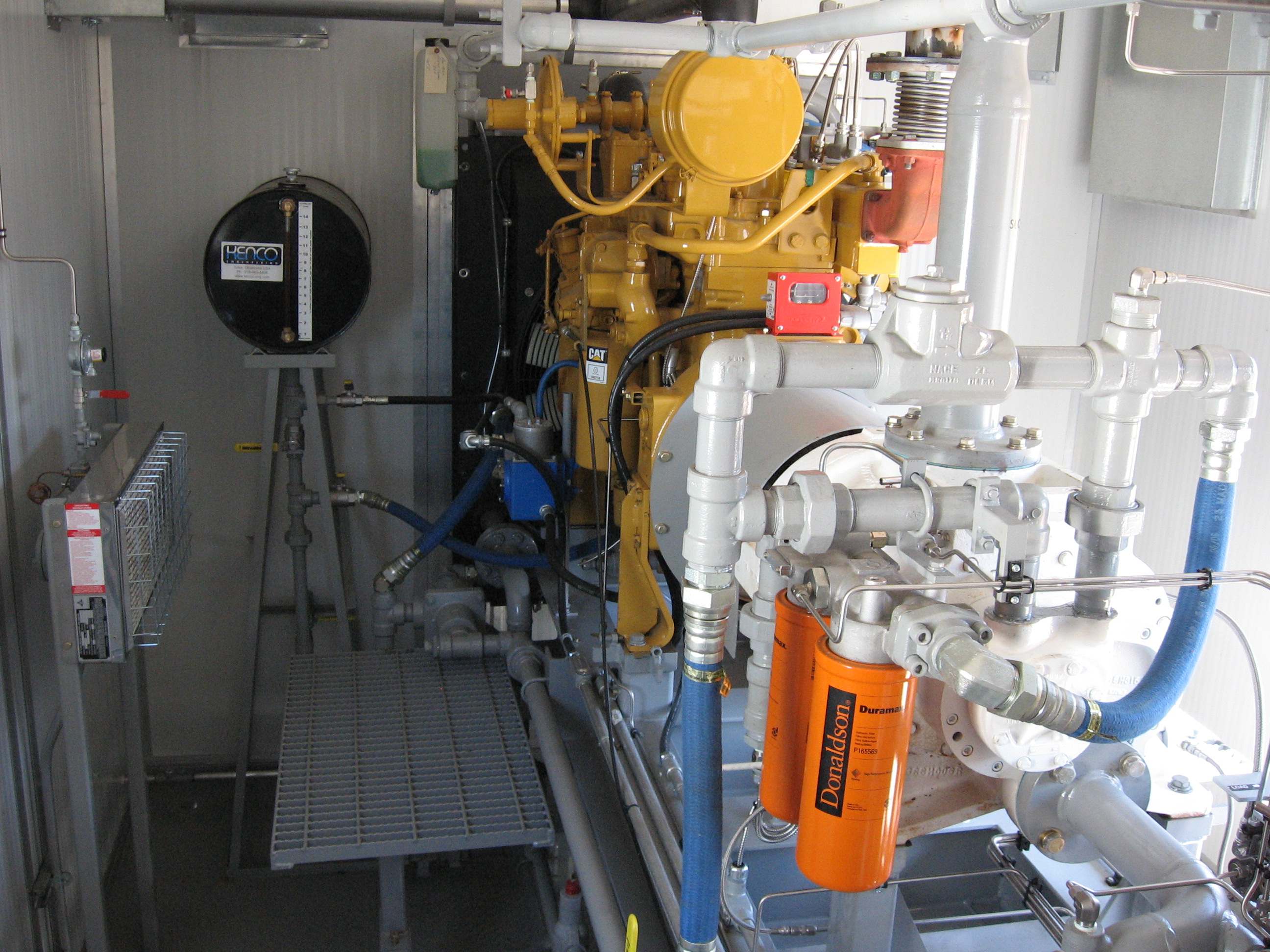

UnitSummary |

|

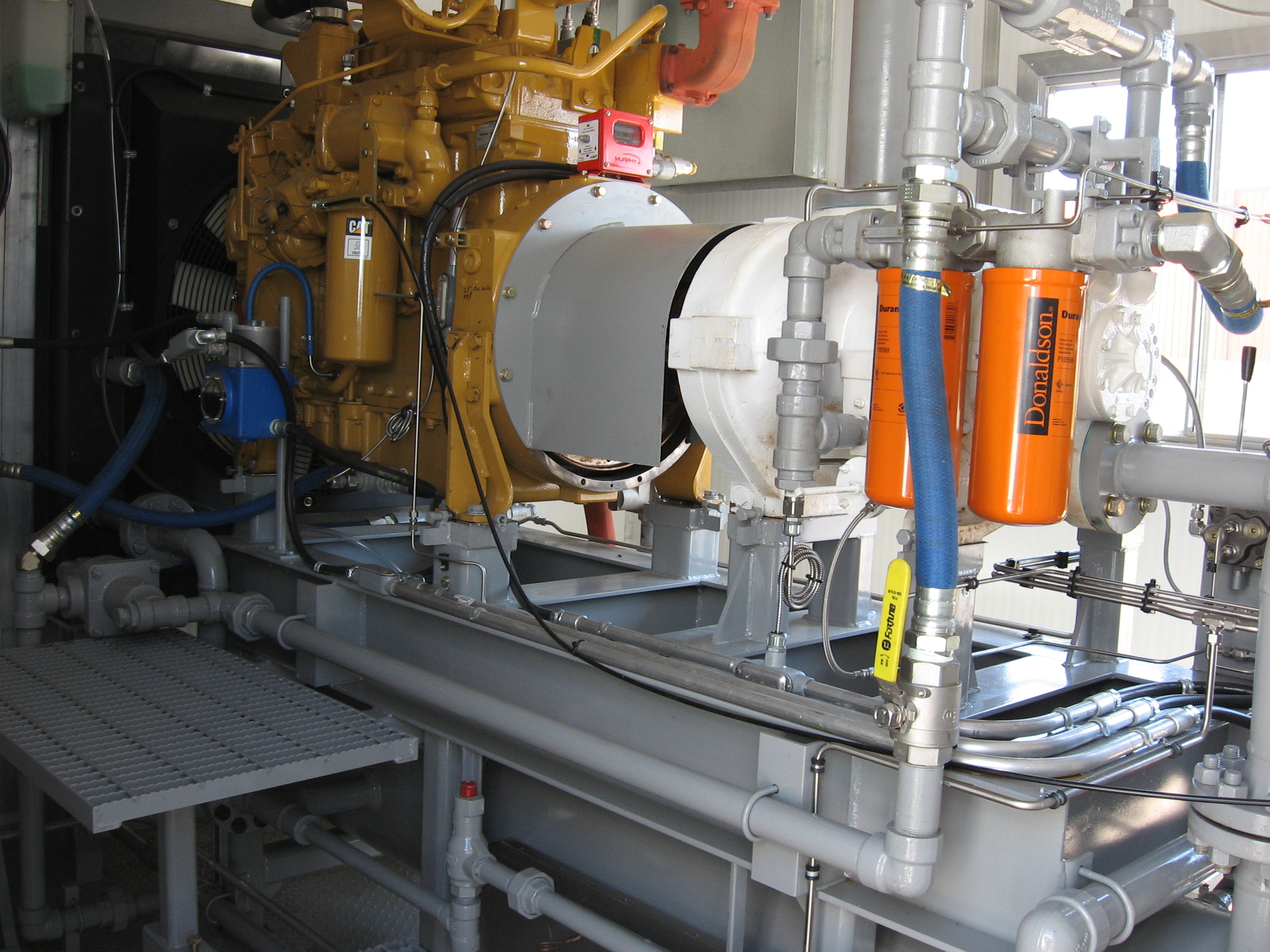

Compressor: | Gardner Denver SSH (177mm) |

Driver: | Caterpillar 3304 NA |

Suction Scrubber Vessel: | 18” OD integrated horizontal vessel (c/w filter) |

Blowcase Vessel: | Optional |

Lube Oil (coalescing) Vessel: | 18” OD x 101” s/s Horizontal Lube Oil Separator |

EJW Cooler: | Global Heat Transfer GHT 23001 |

Compressor Lube Oil Cooler: | Brazed aluminum bar & plate cooler EHRIS |

Compressed Natural Gas Cooler: | Brazed aluminum bar & plate cooler EHRIS |

Driver Silencer: | 4” Hospital Grade Plus exhaust |

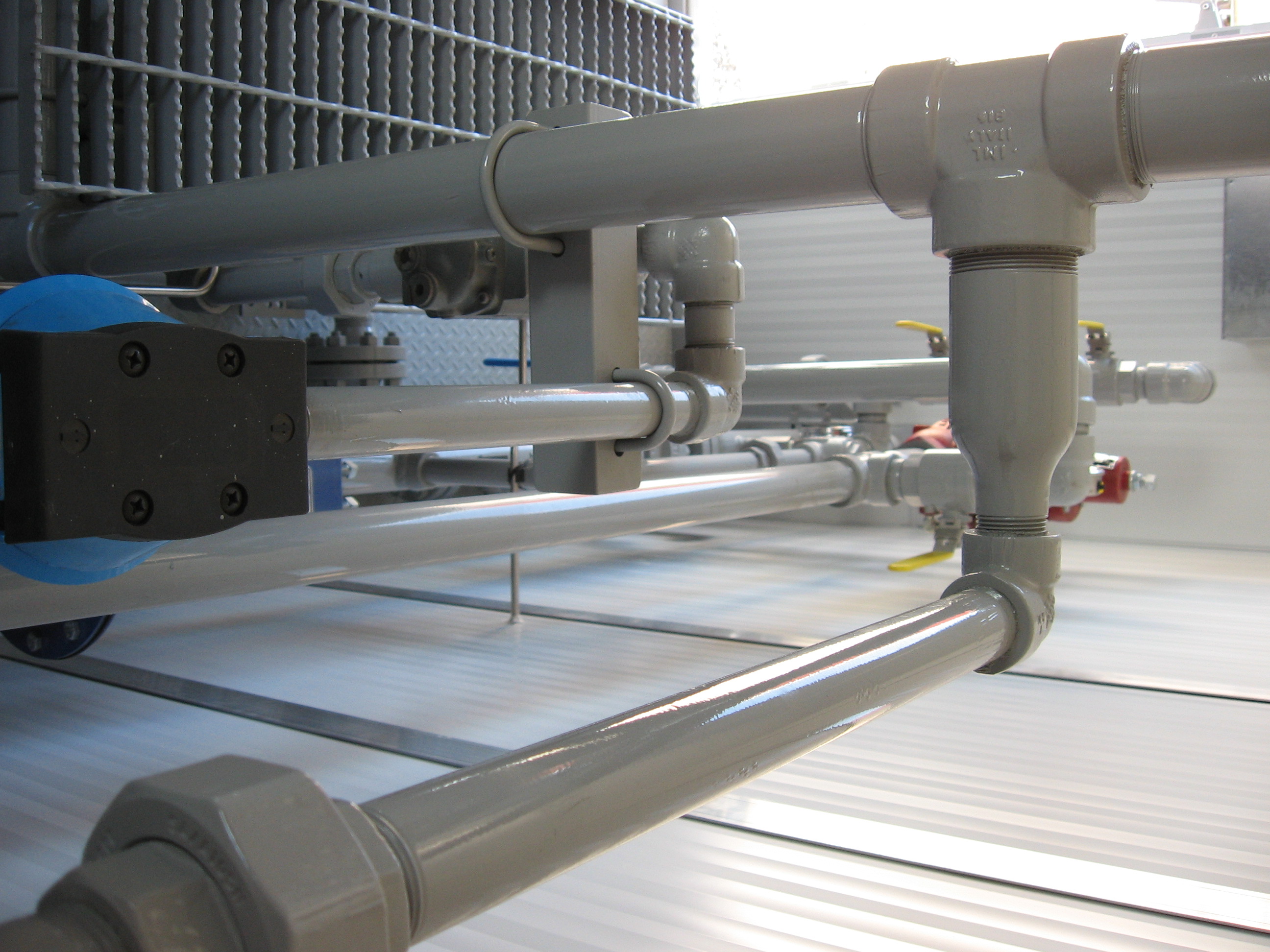

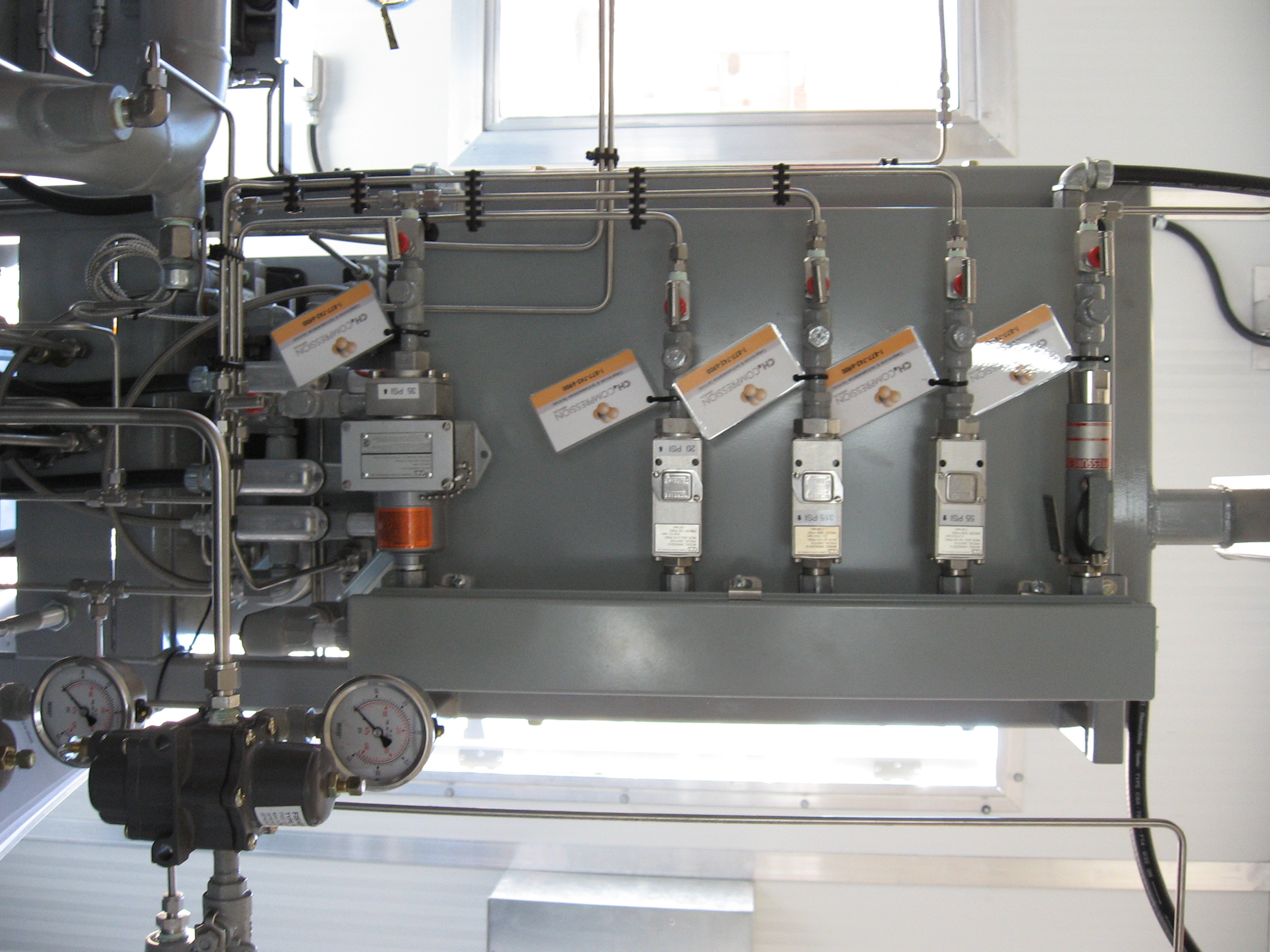

Suction Controls: | 2” V200 V-ball control valve |

Control Panel: | Altronic class I zone II |

Packaging & Enclosure: | Skid mounted; fully insulated building |

| c/w two doors and one window |

Sour Specification | 1/8” corrosion allowance, 100% X-Ray on all welded process piping |

| and vessels. Process pipe welding completed with a registered weld procedure with documented hardness below 200HBN, therefore PWHT not included. |

Commisioning / Start Up: | Complete start up and commissioning services by highly trained and experienced Vortex field personnel. (not included in scope of supply price) |

Operating parameters: | 0 to 50 psig inlet |

| 300 psig discharge |

| Please note: 350 psig discharge option available upon request. |

Skid EdgeConnections: |

|

Inlet: |

4” 300 ANSI |

Discharge: | 2” 300 ANSI |

Vent: | Blowdown header 2” NPT |

Fuel / Start Gas: | 1 ½” NPT Auxiliary fuel/ start gas |

Liquid Drain: | 1” NPT Liquid drain |

Oil Drain: | 1” NPT Engine oil drain |

Rotary ScrewCompressor: | |

Screw: |

Gardner Denver SSH (177mm) gas screw compressor |

Suction: | · Maximum 50 psig |

Discharge: | · Maximum 350 psig |

| · Cast iron housing |

| · Nodular iron rotors |

| · Turn valve capacity controller |

| · Load/Unload single lever detent control valve |

| · Fixed Vi (3.0) |

| · 3” 300 ANSI cone strainer |

| · 40 type mesh |

| · 150% open area |

| · 3” 300 ANSI full flow inlet check valve |

| · 3” x 15” s/s flex joint |

Filtration: | · Donaldson dual oil filters |

| · DPI gauge c/w shutdown |

* Bearings: Cylindrical Roller bearings at the inlet end. Time proven tapered roller bearings at the discharge end. These bearings have reduced friction providing lower rotation speeds and longer life | |

** Rotors have asymmetrical "Kypho" profiles for maximum efficiency over their entire operating range delivering an increase of 3 to 5 % operating efficiency. This improved profile also provides tighter seals which reduce slippage and eliminate vibration. The larger rotor diameters also provide more compression per RPM, reduced compressor | |

Compressor Driver, NaturalGas: | |

Driver: |

· Caterpillar 3304 NA |

Power: | · 95 HP (71 KW) |

Cylinders: | · Four cylinder, In-line |

Bore & Stroke | · 121mm Bore, 152mm Stroke |

| · Altronic III (Class 1, Zone 2) Magneto ignition |

| · Crankcase E-vac system |

| · Murphy (VS-2) high vibration switch |

Shutdown Switches: | · Kenco auto oil level controller c/w shutdown |

| · Murphy low engine coolant level switch |

| · High Engine RPM/Engine overspeed switch |

| · High EJW Temperature |

| · Low engine oil pressure switch, (20 psi dropping) |

| · 15 Gallon engine oil day tank |

| · Sight glass |

| · Manifold vacuum gauge shutdown |

Gas Starter: | · TDI Pre-engaged low pressure pneumatic starter |

| · Panel mounted start button |

| · 1 ½” start gas piping |

Exhaust System | · 4” Hospital Grade Plus Silencer |

| · Expansion joint |

| · Rain |

For all purchase inquiries, please contact us via email at cody@energyauctions.ca or telephone at (403) 771-3984

- 5% GST (Goods & Service Tax) where applicable on all sales will be applied.

- International tax exemption rules will apply.

- Buyer will receive an invoice immediately following confirmation, wiring instructions for payment will accompany.

- All items are sold "as is, where is" unless otherwise stated in the "details description".

Send a quote/offer to receive the listing owners contact details now.