300 ANSI Sep Blowcase (NEW)

- NEW

- Item No. EA0000350

- Share

Details

- Quantity:

- 1

- Status:

- NEW

- Unit Type:

- Separator

- Location:

- Stettler

- Listing Date:

- 21/04/2020

Description

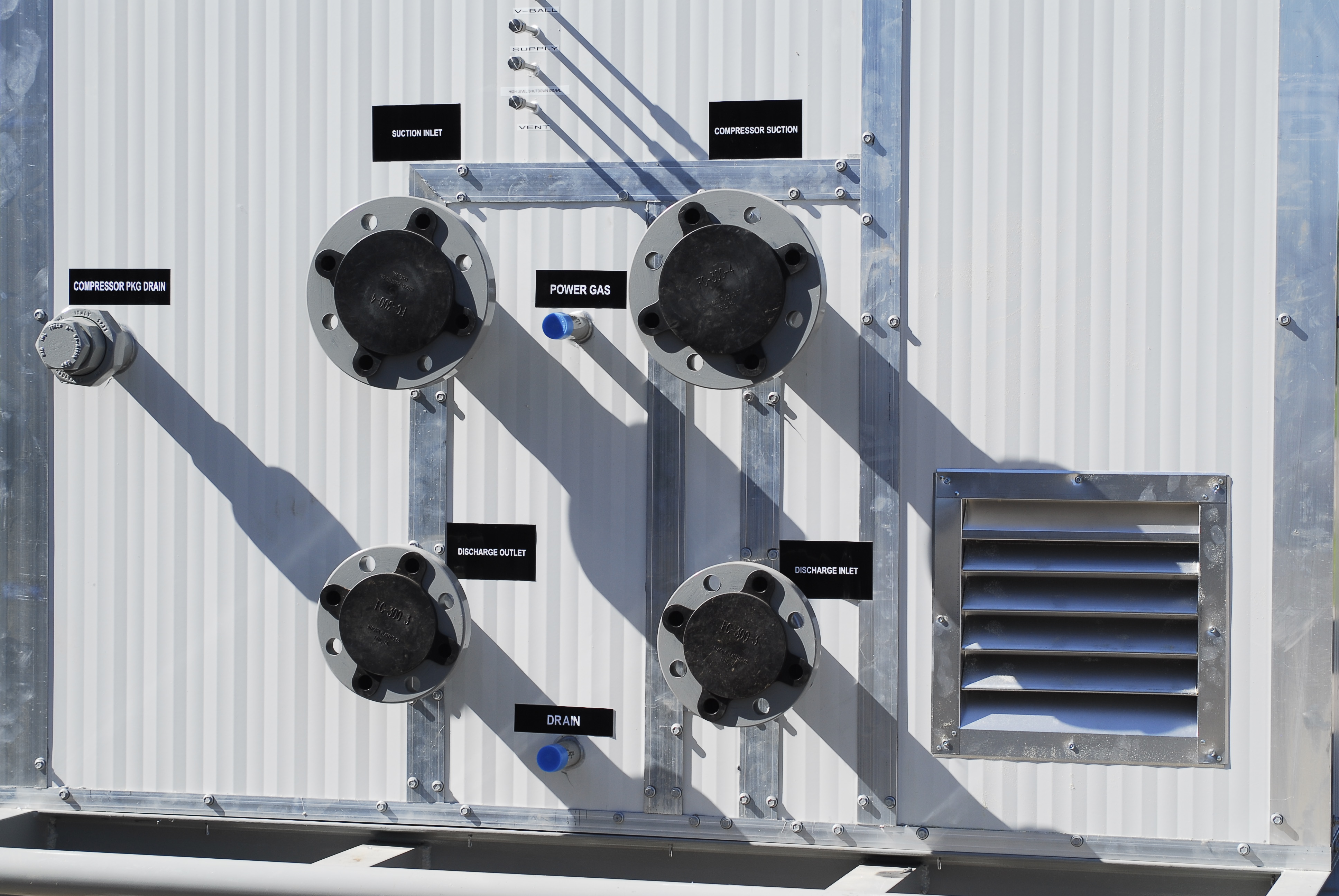

Skid Edge Connections:

• Low Pressure Inlet: 4” 300#

• Low Pressure Outlet: 4” 300#

• High Pressure Inlet: 3” 300#

• High Pressure Outlet: 3” 300#

• 3/8” SS Tubing for V-ball control

• 3/8” SS Tubing for Pneumatic Signal for High Level Shutdown

• 3/8” SS Tubing for Instrument Supply

• 1” Liquid Drain

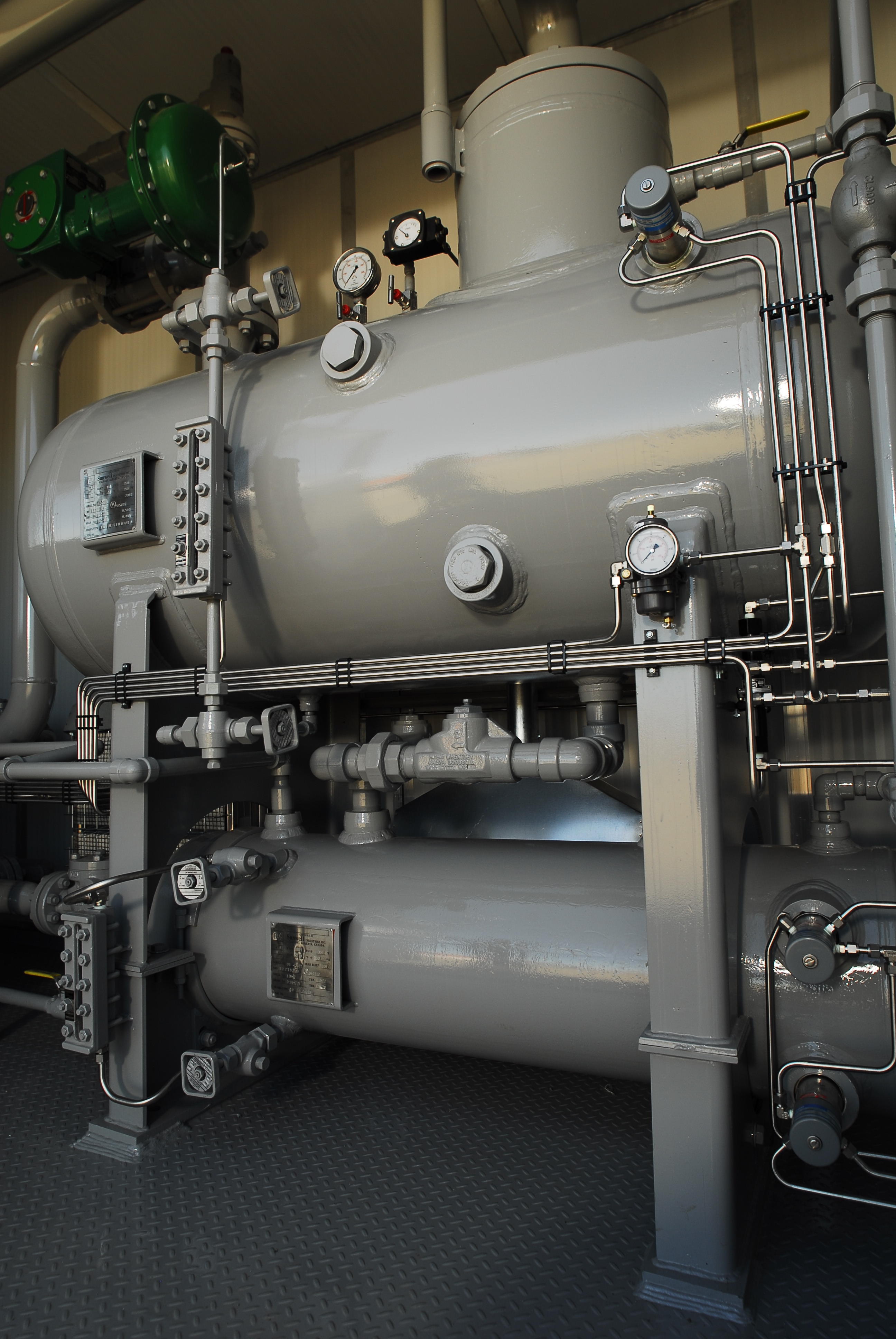

Suction Scrubber:

• 30” OD x 54” s/s Horizontal vessel rated @ 350 psig @ 350°F

• Pressure Safety Valve – 1 ½” NPT x 2” NPT set @ 350 psig, G orifice, Sour

• C.R.N registered (AB, BC, SK)

• ABSA compliant

• 4” 300# Inlet gas nozzle

• 4” 300# outlet gas nozzle

• 16”OD Discharge gas boot

• Inlet filtration DPI gauge

• 2 Micron coalescing filter

• 100% X-Ray

• Stress relieved

• 1/8” Corrosion allowance

Blowcase Assembly:

Blowcase Vessel:

· 16”OD x 52” s/s Horizontal vessel

· ABSA compliant life – 1 million dump cycles

· 350 psig @ 350°F

· Pressure Safety Valve – 1” NPT x 1” NPT set @ 350 psig, E Orifice, Sour

· CRN (BC, AB, SK) and ABSA compliant

· 100% X-ray

· 1/8” Corrosion allowance

· Stress relieved

· Balance Line (to inlet separator)

· Saddle mounted below inlet separator

Controls / Nozzles:

· 2” 6000# NPT Inlet

· 1” 6000# Power gas inlet nozzle

· 2” 300 ANSI RFWN (Liquid dump outlet c/w internal siphon pipe)

· 2” 6000# NPT (High level control switch)

· 2” 6000# NPT (Low level control switch)

· 1” 6000# Balance line coupling (to inlet separator)

· Two 3/4” 6000# (Sight glass nozzles c/w sight glass)

· 1” 6000# (Manual drain nozzle)

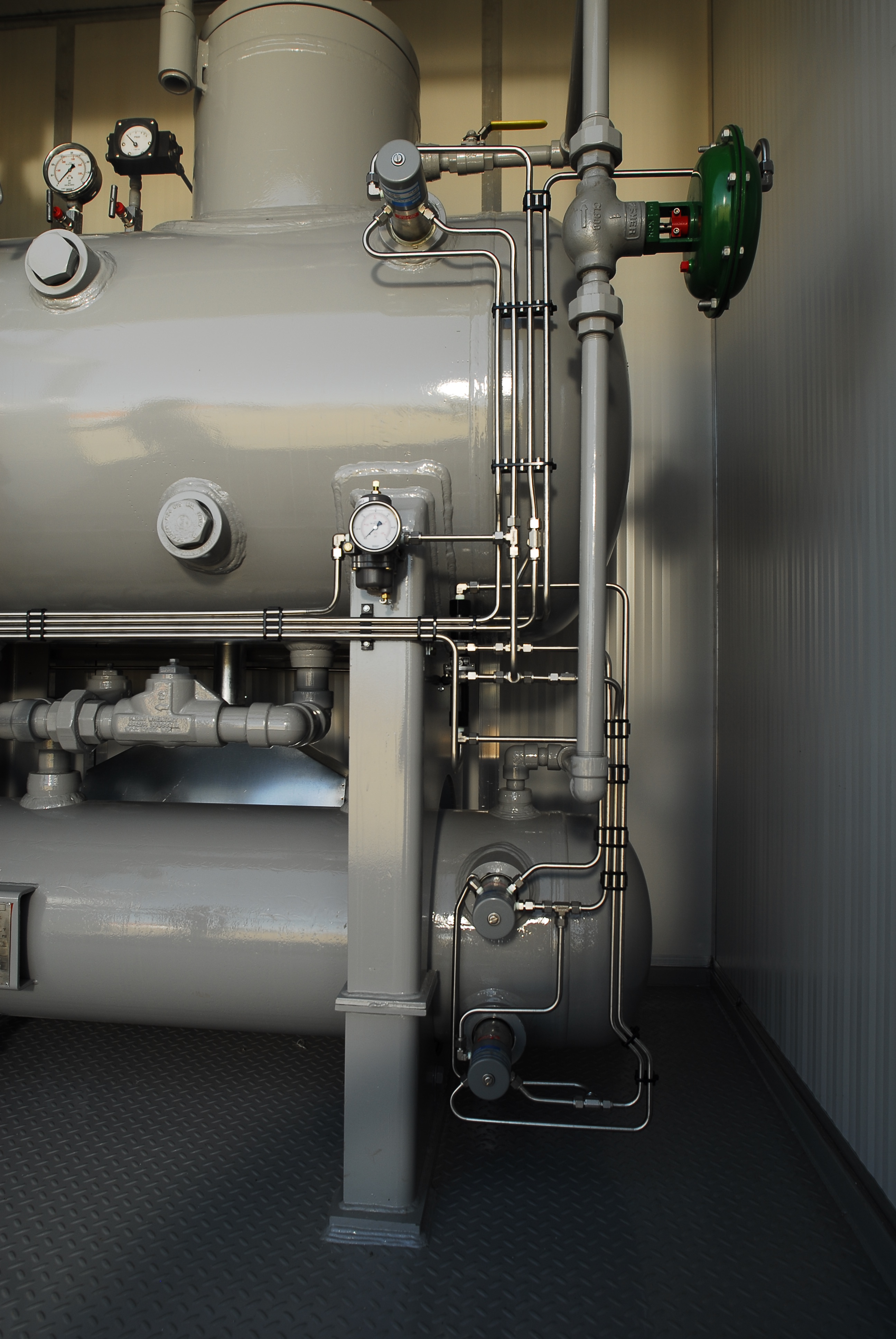

Piping & Controls:

· 3” 300# V-ball c/w connection point for off skid control

· 3” 300# Globe valve (to induce differential for blowcase function)

· 1” Sch 80 Balance line c/w inline actuated control valve

· 1” D2 Dump valve (balance gas control)

· 2” Sch 80 NPT Dump line (separator to blowcase c/w check valve)

· 2” Sch 80 BW Dump line (blowcase to discharge line c/w check valve)

· 1” Sch 80 Power gas line (upstream of globe valve to blowcase) c/w inline actuated control valve

· 1” D2 Dump valve (Power gas control)

· AMOT 2-way valve for blowcase cycling

· 2” SOR 1530 Level Switch for upper and lower level control

· 3/8” Instrument gas tubing

Skid:

· 14’ L x 6’-3” W x 8” H

· C8 x 12 Runners

· 3/16” checker plate floor

· Floor drain

· Live roll connection – continuous longitudinal wide flange runners end to end

· Sandblasted

· Endura industrial paint finish

Building:

· 12’ L x 6’ W x 8’8” H

· Insulated thermal panel Vortex building

· R12 Insulation

· Sloped Roof for drainage

· White exterior / interior

· One double door

o Weather stripping

o Check chain

o Locking and panic hardware

o 24” x 24” windows

· One 3’ x 3’ sliding window

· Two 12” x 12” louvered vents

· Two access panels

· One 8,000 BTU Catadyne 12” x 24” heater

o Vent hood

o Protective grill

o 25’, 12 volt starter cables

o Pressure regulator

o Class I, Zone II, Group D, CSA approved

· One 16,000 BTU Catadyne 24” x 24” heater

o Vent hood

o Protective grill

o 25’, 12 volt starter cables

o Pressure regulator

o Class I, Zone II, Group D, CSA approved

For all purchase inquiries, please contact us via email at cody@energyauctions.ca or telephone at (403) 771-3984

- 5% GST (Goods & Service Tax) where applicable on all sales will be applied.

- International tax exemption rules will apply.

- Buyer will receive an invoice immediately following confirmation, wiring instructions for payment will accompany.

- All items are sold "as is, where is" unless otherwise stated in the "details description".

Send a quote/offer to receive the listing owners contact details now.